The intelligent coking platform based on big data integrates all data of factory by collecting, saving, analyzing and applying. Through by the construction of visual monitoring ,factory-level smart scheduling,plant life cycle management, coordinated management,production process optimization and production control ,the intelligent coking platform can improve production efficiency and output of the coke oven, reduce energy consumption ,pollutant emission and labor cost during the production。It could also balances overall production, maximizes resources utilization, ensures safe and stable production with efficient operation of equipment and provides information support for decision maker at the same time.

contact

data collection

Flexible allocation of factory data clustering for collecting relevant data covering each process

storage

Optimization,management and backup storage for collected data

factory visual display

including process frame, plant monitoring frame,custom report and custom data query statistics.

application portal

interactive platform for publishing and carrying out required application server

Big data platform complete customization

Complete customization for fundamental big data platform according to intelligent manufacturing.

data base

Providing fundamental data base of application development and publishing on the basis of big data platform,which includes algorithm and mechanism component library,expert knowledge base and so on.

intelligent production planing

Including static and dynamic plan scheduling and production plan performing assessment.

intelligent scheduling

Making coordination according to process,device state and material consumption to ensure plan implementation as benchmark.

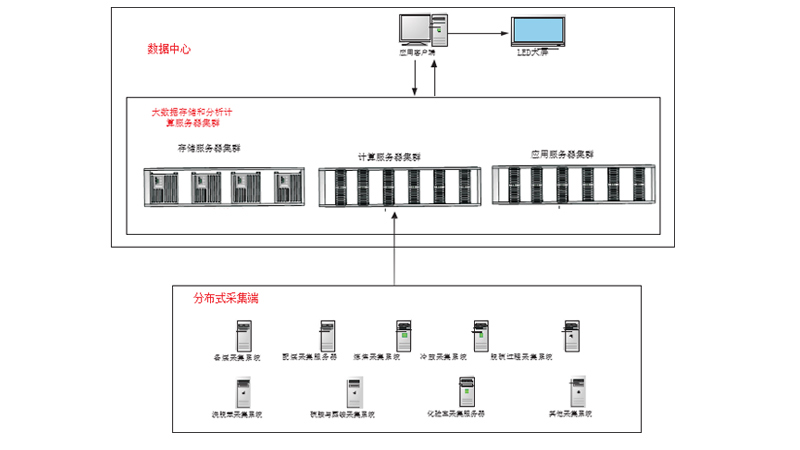

System hardware includes distributed collection server,big data memory& analytical computing server cluster,application client and LED display.Distributed collection server converts field industrial data storage interface into big data platform reading interface.Big data platform carries out data secure storage and management,analytical computing server takes charge of data reading, processing,calculating and turning into available service.

copyright Hunan Qianmeng Industrial Intelligent System address:28 Kangwang Industrial Park, Yueyang record number:湘ICP備20000218號-1business license

Technical Support:Competition network